Pennsylvania Grown

All our wood is sustainably harvested from the Pennsylvania forests surrounding our studio. We use this locally-sourced lumber to create one-of-a-kind custom pieces from dining tables to coffee tables - each designed through collaboration between me and my client. We'll find the perfect slab with striking grain and live edge perfectly suited for your piece, and transform it using timeless techniques of the craft into functional art. The furniture that results uniquely preserves the natural beauty of the wood while meeting personal needs for utility and function. Our custom wood furniture showcases the hidden elegance of raw wood, enhancing your space for decades to come. Let's start a conversation about hand-crafting sustainable wooden furniture for your project.

The Sawmill

Trees are harvested by expert logging crews and then brought to our sawyer in Ohio where each log is carefully examined for the best cut. It takes years of experience and a trained eye to develop the sense of where to slice open a log in a way that reveals it’s character, grain, and shape in the most spectacular way possible.

Drying

All of our slabs are stacked with spacers and air dried for about 2.5 years before being carefully finished in the kilns and brought to a stable working moisture content.

Flattening Slabs

This is one of the most exciting stages, as the true color and grain of each slab is uncovered from the rough sawn surface. The true potential of each piece really starts to shine at this point. Initially a “Hit and Miss” planing is done, simply to reveal the grain and color, and slabs are left thick in order to provide room for flattening to a specific thickness later on when they are selected for projects.

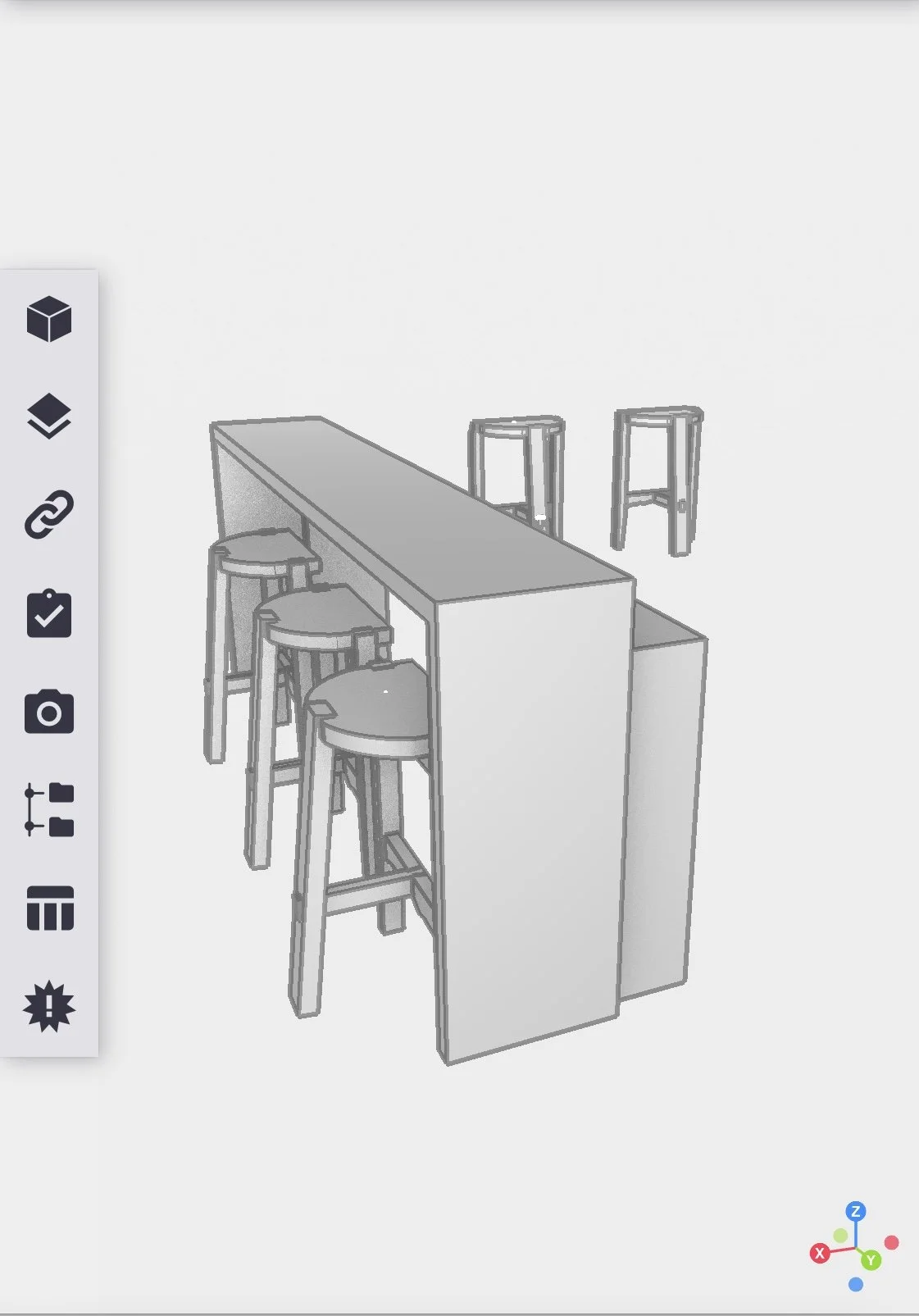

Design

In the initial phases of a custom project ideas and hand sketched concepts are put into a 3D rendering program so that dimensions, proportions, and general construction details can be worked out, but so much of the final design comes from the time spent looking through our slab collection. The wood ultimately determines the overall form of our pieces and it is often a particular slab that inspires a new design.

Crafting

Making use of a combination of machine and traditional hand tools, we personally craft each piece in our shop. This is the place where all the ideas and visions come together and get worked into reality amidst the sawdust, sweat, and work of our hands. It is this time in the shop that keeps our designs grounded, but also what opens it to new possibilities as we learn and appreciate what the wood and our skills are capable of with each new project.

![Morgan_2023_4816[web]_Original.jpeg](https://images.squarespace-cdn.com/content/v1/5c944d4a94d71a963838464c/1697490363238-28AFOZ1T3YIOGFE2V1F6/Morgan_2023_4816%5Bweb%5D_Original.jpeg)

![Morgan_2023_4869[web]_Original.jpeg](https://images.squarespace-cdn.com/content/v1/5c944d4a94d71a963838464c/1704251520673-YQMUEOKJ22X8TVHDORJN/Morgan_2023_4869%5Bweb%5D_Original.jpeg)

![Morgan_2023_4833[web]_Original.jpeg](https://images.squarespace-cdn.com/content/v1/5c944d4a94d71a963838464c/1704251521467-9I27KE82KP0DQ7KAS1I0/Morgan_2023_4833%5Bweb%5D_Original.jpeg)